Our Services

Our Services

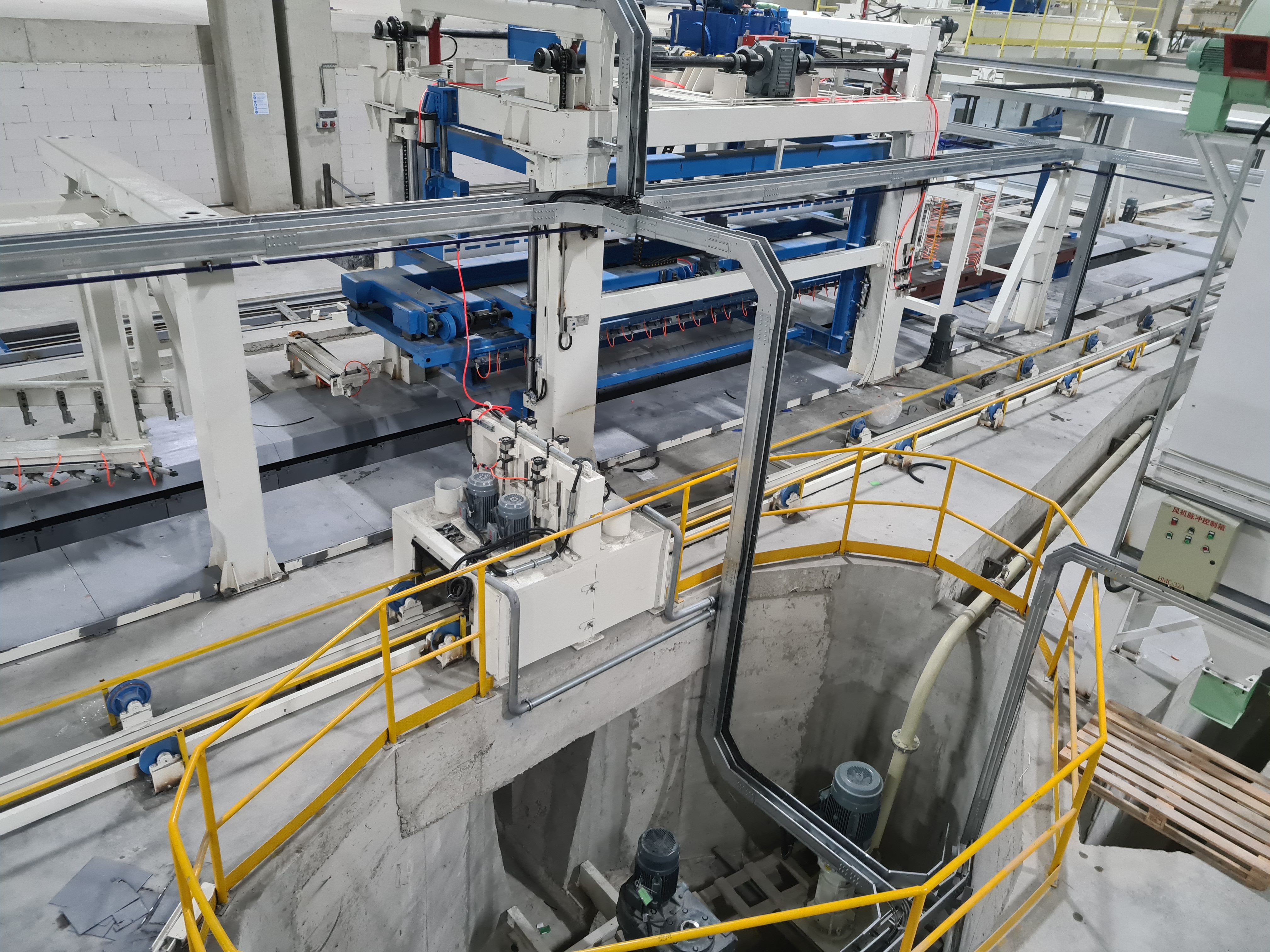

If you want to own an AAC factory, you are in the right place. We design the world’s most modern AAC plant and provide services tailored to your needs at every stage until production begins.

If you are a machine manufacturing company planning to offer turnkey AAC factories to your clients, we can provide project consultancy and help you integrate your machines into our modern AAC facility designs.

Steps to Prepare Your AAC Facility for Operation:

1. Evaluating market share based on the location of the AAC plant and determining the production capacity.

2. Designing the most economical and compact AAC factory prototypes suitable for the market share.

3. Assessing the raw materials and mineral resources required for production.

4. Providing consultancy for obtaining necessary mining and environmental permits for the AAC facility.

5. Presenting the construction and setup costs for the AAC factory, including machinery.

6. Calculating the raw material and energy consumption required during Aerated Concrete (AAC) production.

7. Preparing investment incentive documents for submission to the Treasury if the AAC factory is in an incentive zone.

8. Adapting prototype designs to regulations and preparing architectural, structural, mechanical, electrical, automation, flood prevention, and soil protection plans.

9. Preparing infrastructure and superstructure projects for the AAC facility.

10. Developing reinforcement and formwork designs for machinery foundations in the AAC plant.

11. Preparing technical specifications for all construction works and making them ready for tender.

12. Constructing infrastructure and superstructure with our professional construction team, or monitoring the process if the AAC factory is overseas.

13. Preparing specifications for all machinery in the AAC facility based on years of experience testing machines, making them ready for tender and order.

14. Coordinating the order and manufacturing processes of all machines required for production in the AAC plant.

15. Preparing ideal recipes for Aerated Concrete (AAC) products to be produced.

16. Providing experienced personnel for periodic maintenance and troubleshooting of machines post-production.

17. Offering consultancy during the acquisition of national approval certificates for the Aerated Concrete products.

18. Preparing a staff list with qualifications required for AAC factory personnel.

19. Offering support for all standards related to Aerated Concrete (AAC) production.

20. Training sales staff on AAC sales strategies and providing the necessary support for marketing the produced materials.