AAC Facilities We Design

AAC Facilities We Design

The AAC plants we design:

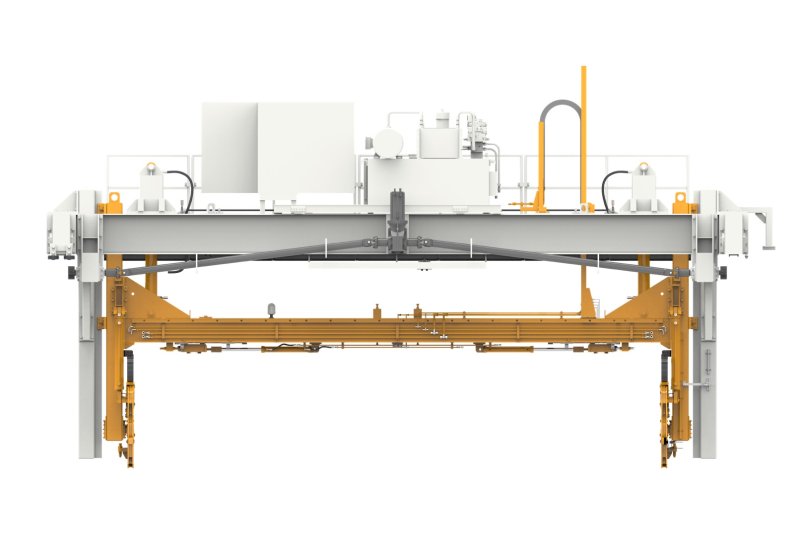

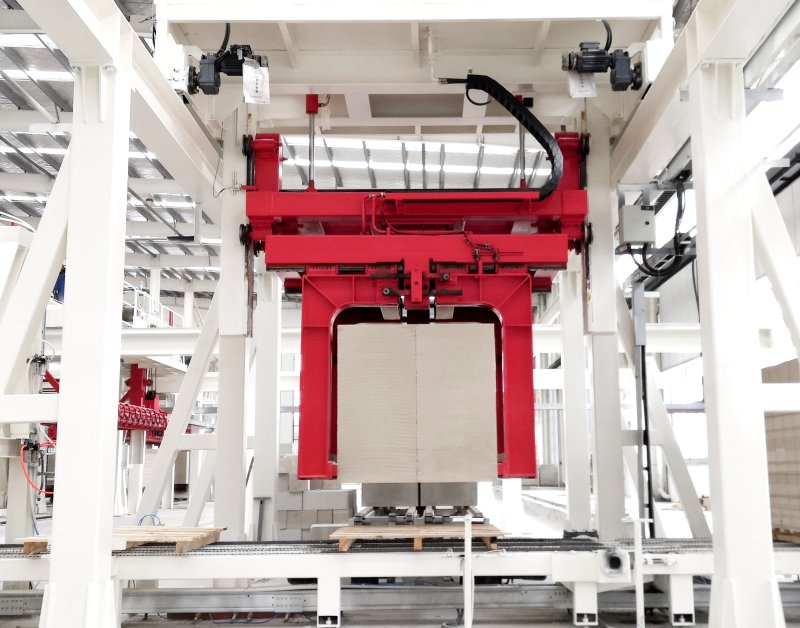

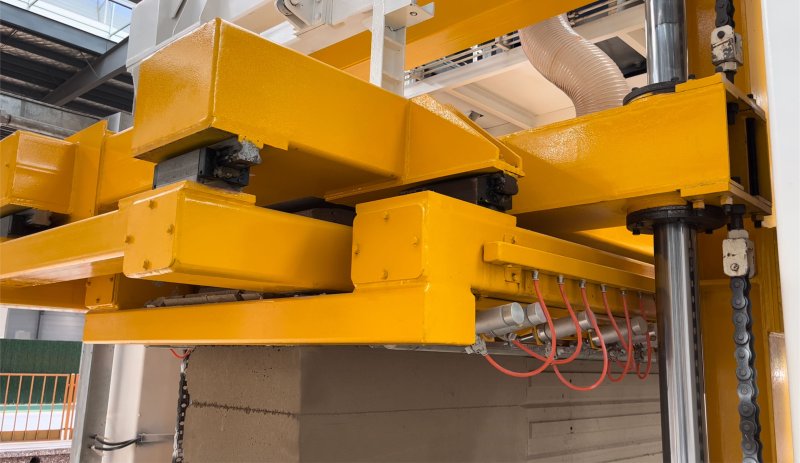

1. The AAC plants we design are equipped with the latest technology.

2. Each AAC factory features a modern and innovative structure.

3. Our Autoclaved Aerated Concrete (AAC) facilities enable easy control of all machinery from a single control room using advanced automation systems.

4. These AAC factories require minimal human labor during the production process.

5. Every Aerated Concrete (AAC) plant operates on a zero-waste principle.

6. Our designs deliver world-class production capacity and performance efficiency.

7. The AAC facilities are structured to allow easy capacity expansion if needed in the future.

8. Each AAC factory maximizes production efficiency and achieves optimal aerated concrete production capacity.

AAC Facilities We Design

The AAC facility we design is tailored to market demand, allowing initial operations to start with a smaller production capacity and lower investment. Over time, capacity can be increased through additional investments, reaching levels such as 130,000 m³, 180,000 m³, 450,000 m³, and 800,000 m³.

This AAC plant is capable of producing a variety of products, including:

• G2-class blocks, used in reinforced concrete buildings.

• G4-class blocks, denser blocks for load-bearing masonry buildings.

• G0.5 insulation panels, used as cladding for thermal insulation in buildings.

• G1 hollow blocks, suitable for use as lightweight slabs in construction.

• Reinforced G3 panels, used as walls in industrial facilities by embedding steel reinforcements.

• Roof panels (Reinforced G3-G4).

• Lintels and sills, used to span door and window openings after wall construction.

• Adhesive mortar, specifically designed for assembling AAC blocks.

The flexible production capacity and diverse product range ensure that this Autoclaved Aerated Concrete (AAC) factory can meet a wide variety of construction needs efficiently.